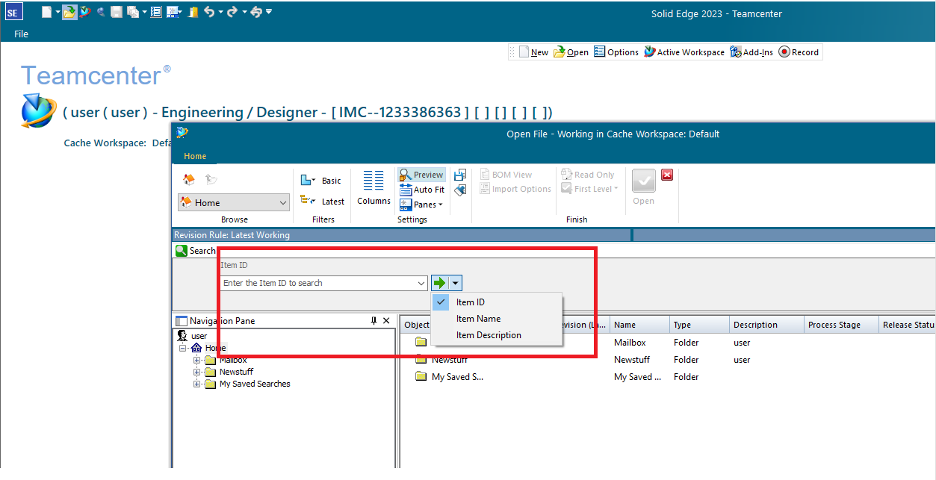

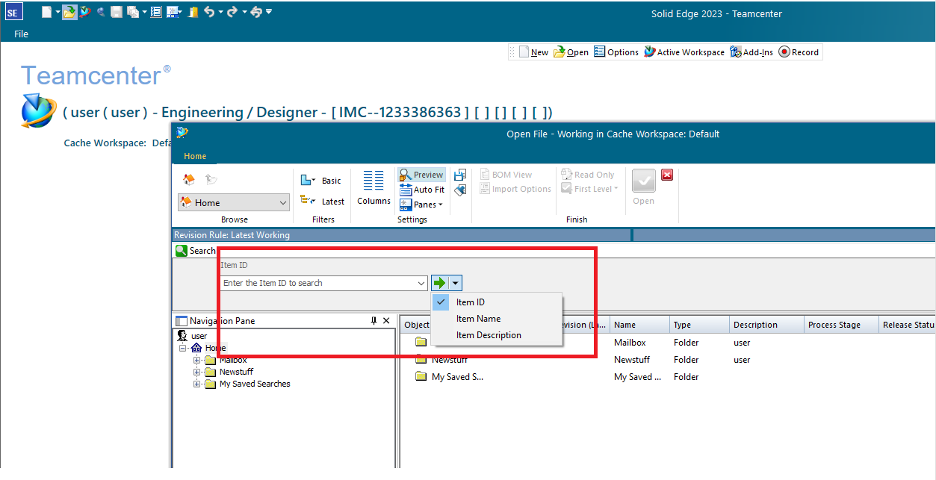

Extend Solid Edge & Teamcenter Search Capabilities

Read More

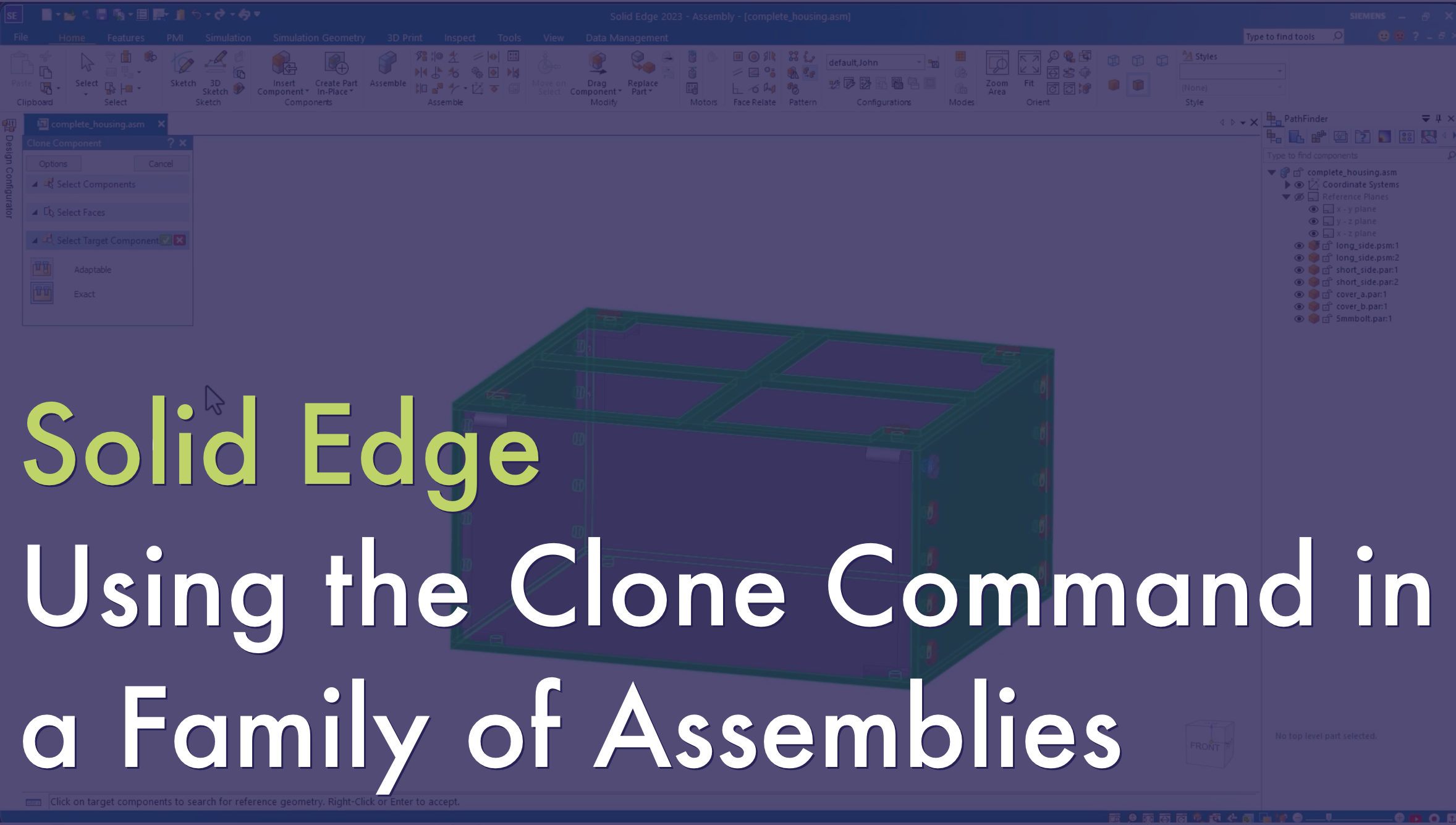

Using the Clone Command with a Family of Assemblies

Read More

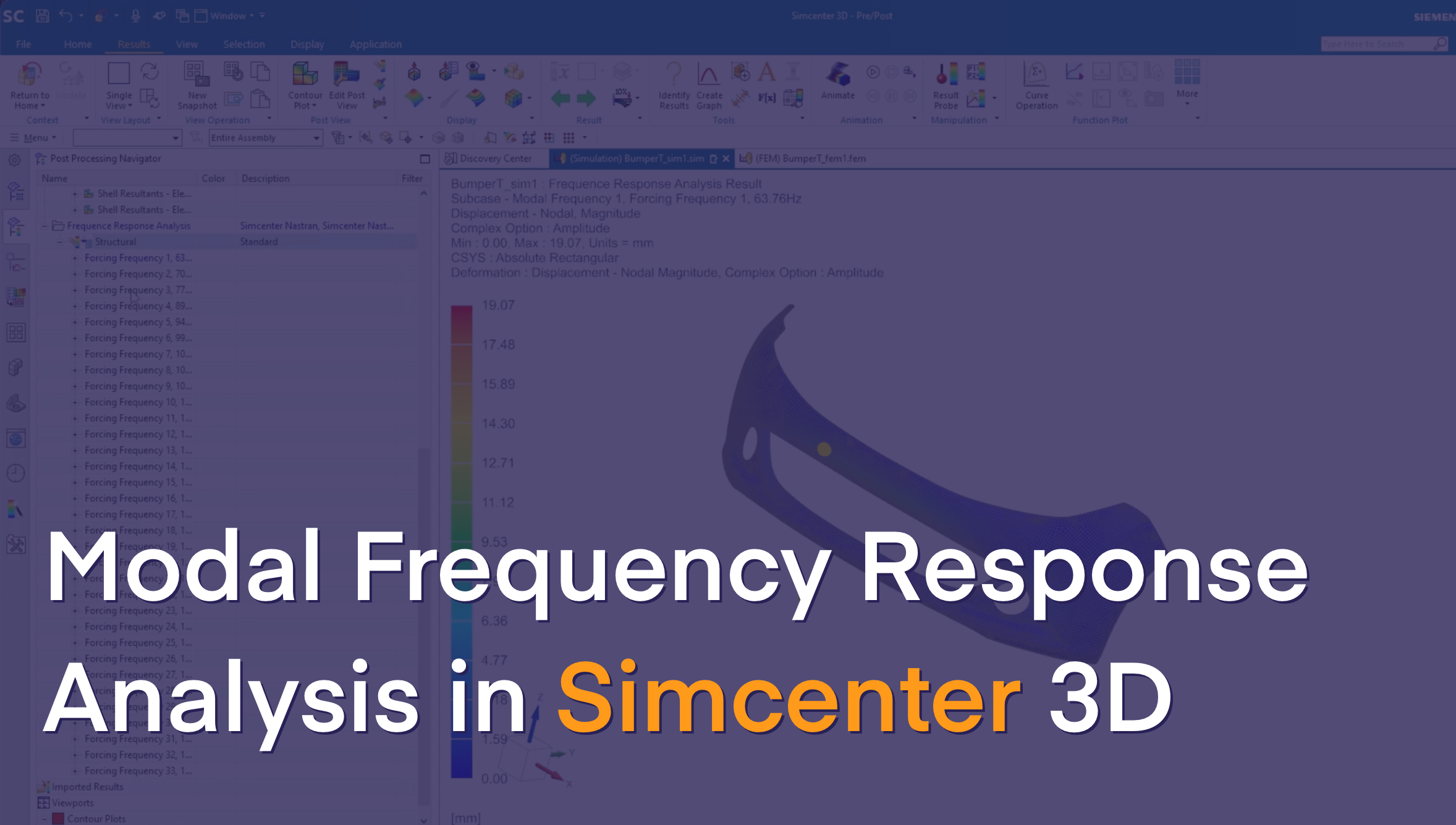

Learn how to set up a Frequency Response Analysis in Simcenter 3D to assess a vibrating body's response and avoid system failure.

Read More

Maximize Your Markforged 3D Printer's Potential: Unlock Efficiency and Innovation

Read More

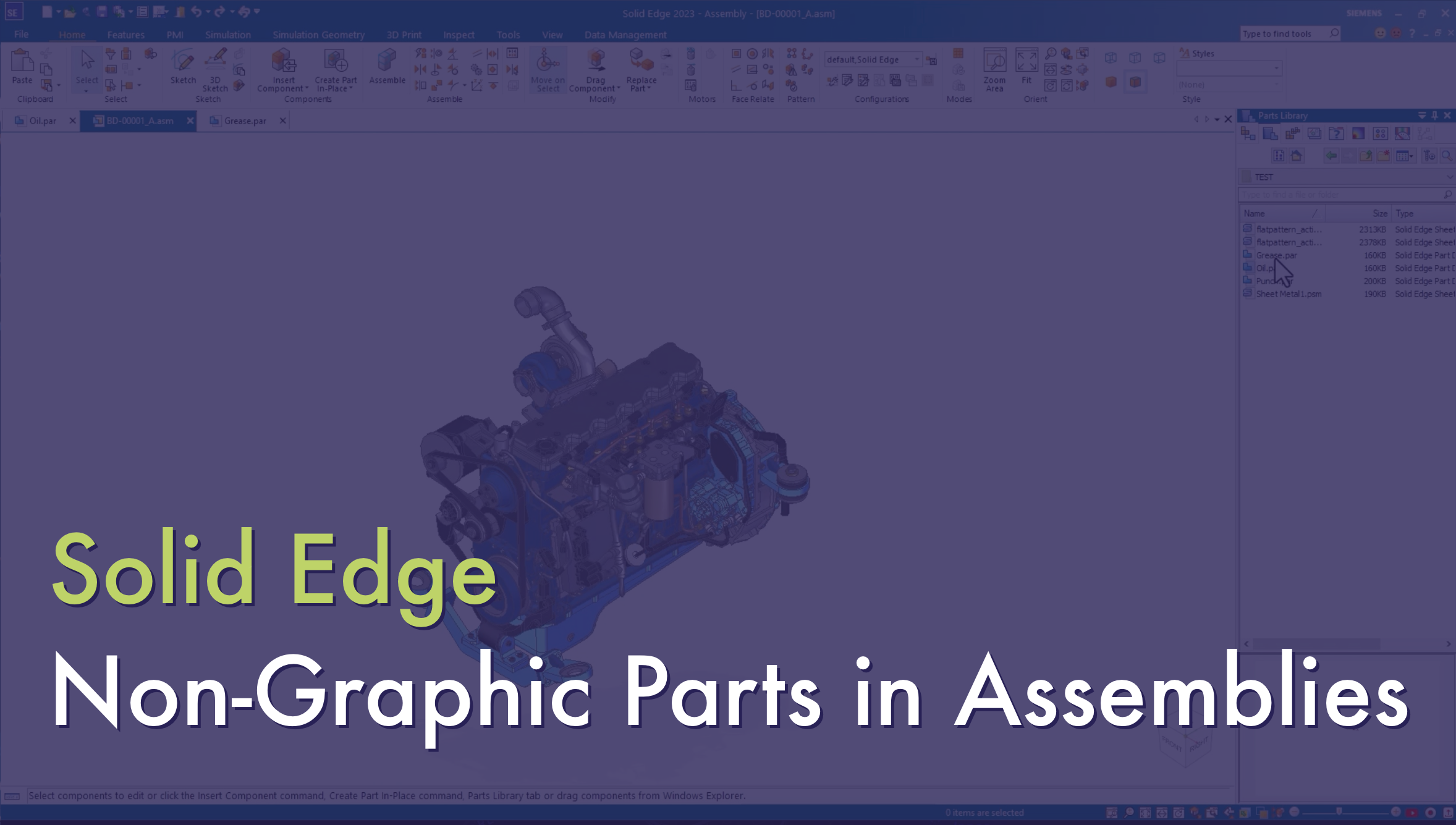

Sharing with you how to create and place non-graphic parts in assemblies.

Read More

The following example outlines a supported procedure using Teamcenter Access Manager to allow a group of users to access only specific documents that have been reviewed and released to production.

Read MoreDesignfusion is the largest dedicated solution provider of Siemens PLM software in North America. With an expert support team and a decade of history in the industry designfusion is the #1 choice for companies looking to best enhance their software acquisition.

305 Milner Ave, Suite 308,

Toronto, Ontario, M1B 3V4

Canada

Phone: 416 267-5542

Toll Free: 1-888-567-3933

2734, rue Étienne Lenoir Laval, Quebec. H7R 0A3

Canada

Phone: 514-761-5682

Toll Free: 1-866-534-5682

565, rue Shefford, Suite 1

Bromont, Québec, J2L 1C2

Canada

Phone: 450-534-5682

Toll Free: 1-866-534-5682

1400 E Touhy Ave, Suite 477

Des Plaines, IL 60018

USA

Phone: 847-439-0555

Toll Free: 1-866-921-1830

3477 Corporate Parkway, Suite

104 Center Valley, PA 18034

USA

Toll Free: 1-866-921-1830

151 Castleberry Ct. Ste.

CMilford, OH 45150

USA

Toll Free: 1-866-921-1830

60 Scarsdale Rd, Unit 119

Toronto, Ontario, M3B 2R7

Canada

1919, Boulevard Lionel-Bertrand Suite 101, Boisbriand,

QC J7H 1N8, Canada