This capability ensures the identification of the appropriately controlled preload necessary to enhance structural stability, minimize fatigue, and extend the overall reliability of mechanical connections across a spectrum of diverse applications.

Read More

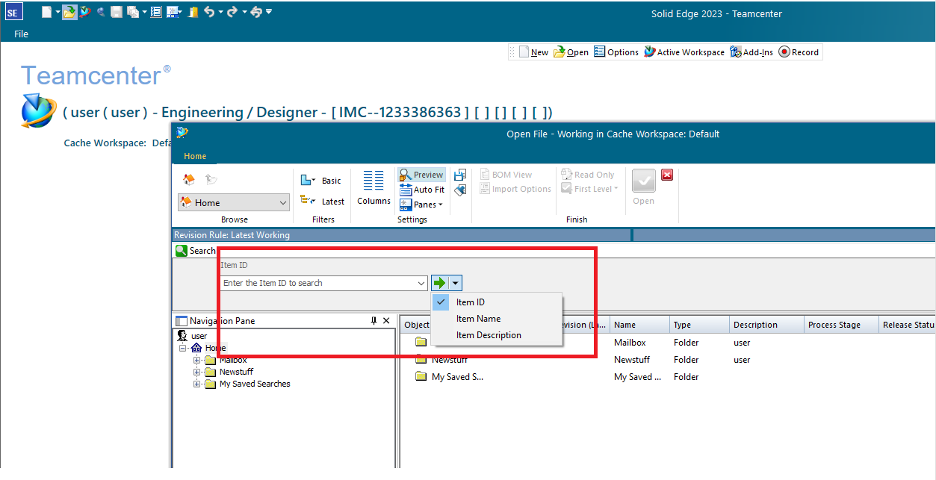

Extend Solid Edge & Teamcenter Search Capabilities

Read More

Using the Clone Command with a Family of Assemblies

Read More

Learn how to set up a Frequency Response Analysis in Simcenter 3D to assess a vibrating body's response and avoid system failure.

Read More

Maximize Your Markforged 3D Printer's Potential: Unlock Efficiency and Innovation

Read More

Sharing with you how to create and place non-graphic parts in assemblies.

Read MoreDesignfusion is the largest dedicated solution provider of Siemens PLM software in North America. With an expert support team and a decade of history in the industry designfusion is the #1 choice for companies looking to best enhance their software acquisition.

305 Milner Ave, Suite 308,

Toronto, Ontario, M1B 3V4

Canada

Phone: 416 267-5542

Toll Free: 1-888-567-3933

2734, rue Étienne Lenoir Laval, Quebec. H7R 0A3

Canada

Phone: 514-761-5682

Toll Free: 1-866-534-5682

565, rue Shefford, Suite 1

Bromont, Québec, J2L 1C2

Canada

Phone: 450-534-5682

Toll Free: 1-866-534-5682

1400 E Touhy Ave, Suite 477

Des Plaines, IL 60018

USA

Phone: 847-439-0555

Toll Free: 1-866-921-1830

3477 Corporate Parkway, Suite

104 Center Valley, PA 18034

USA

Toll Free: 1-866-921-1830

151 Castleberry Ct. Ste.

CMilford, OH 45150

USA

Toll Free: 1-866-921-1830

60 Scarsdale Rd, Unit 119

Toronto, Ontario, M3B 2R7

Canada

1919, Boulevard Lionel-Bertrand Suite 101, Boisbriand,

QC J7H 1N8, Canada